NIR Hyperspectral / Food Technology

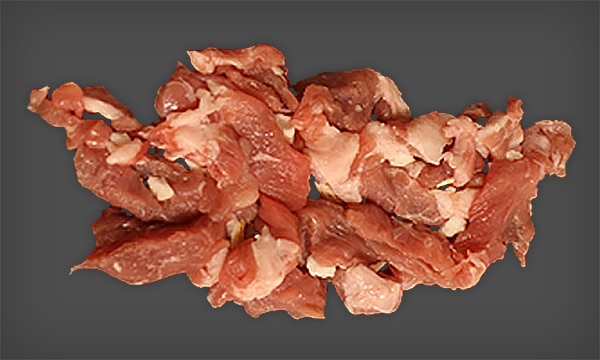

NIR hyperspectral inspection for in-line and industrial inspection of product chemical composition such as fat saturation, dry matter content, mixed product composition, etc).

Industrialization of NIR Hyperspectral Inspection.

Vision Partners introduces inspection solutions that leverage NIR hyperspectral technology to contactlessly analyze the chemical composition of food with high precision at line speed in an industrial food processing environment.

This innovative solution uses a hyperspectral NIR/SWIR line-scan camera and is specifically designed to meet the challenges of production environments, combining reliability and robustness with advanced analytical capabilities.

The solution is equipped with a user-friendly interface and offers flexible integration capabilities with upstream PLC and ERP/MES systems. The solution can be delivered as a standalone inspection machine or added to an already existing product line.

Vision Partners' solution represents not only an investment in quality control, but also in building consumer trust and protecting brand integrity, even in the most demanding production environments.

Understanding food chemistry

Understand food chemistry with hyperspectral imaging while improving food quality and safety. Vision Partners has experience with several projects where hyperspectral technology is used to make the food chain more sustainable by measuring in-line the (chemical) composition of a product in an industrial environment.

Hyperspectral imaging delivers higher quality images

That means we can assess food quality more accurately and provide richer insights than other solutions. Hyperspectral imaging is non-destructive and operates at line speed, in real time.

Hyperspectral applications in the food chain

Solutions from Vision Partners see the chemical composition of food as it passes by at line speed. We collect and process this information in real-time, giving you the insights you need to make your products safer and of higher quality.

Hyperspectral technology easily finds foreign materials such as plastic, rubber and bone. And also indicates where the contamination is located

Maintain margins and meet your target composition requirements.

Hyperspectral technology can measure properties such as tenderness, protein, pH, marbling and color. Reliable, in-line and repeatable.

Benefits of hyperspectral imaging in for food applications

Short-wave infrared spectroscopy (SWIR) provides a rapid and non-destructive method for inspecting and monitoring food quality and is well established in the food industry for laboratory and online use.

This technique makes it possible to determine the composition of samples (e.g., moisture content, protein content, and some) as well as physical characteristics such as (e.g., particle size of ground particles). Many relevant chemical bonds in food samples absorb light at certain wavelengths in the SWIR range (900 - 2500 nm).

These absorption features reveal the chemistry of the sample and can be detected by spectroscopy. The method is ideal for analysis of the average composition of homogeneous samples such as flour. For more complex products, the disadvantage of spectroscopy is that it provides information at only one point in the sample at a time.

Hyperspectral imaging (HSI) combines spectroscopy with imaging. This technique allows for simultaneous pixel-by-pixel analysis of compound or heterogeneous foods. As an imaging technique, hyperspectral imaging requires no contact with the food that destroys or contaminates the sample, and with a proper calibration model, the analysis result can be provided in real time.

Hyperspectral sensors provide information across hundreds of narrow wavelength bands. This provides data on multiple, overlapping absorption bands for different chemical bonds, allowing calibrations to be developed for specific chemical components relevant to food production.