For applying the labels to the cans, the customer already had rotary stations in line where the cans are rotated in the same position and the label is applied to the can. We were able to use this for detecting the dents in the cans all around. This by means of two smart cameras which monitor the bottom and top during rotation.

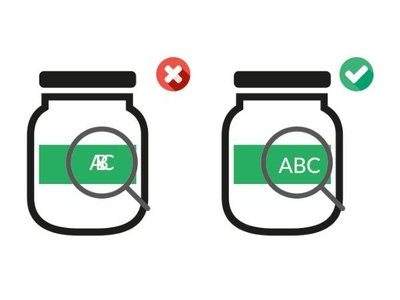

For checking the labels, a separate multi-camera system is provided which checks both the front & back label as well as the special hologram sticker for presence and position relative to a marking in the can itself.

For this label control, the cans do not have to be rotated because here the six cameras are positioned around the can. The rotation of the can while passing through these six cameras may be random and hereby does not affect the operation of the system.

Turn-key solution as an add-on in production line

Vision Partners delivered the solution turn-key and built it as an add-on to the customer's production line including a rittal control cabinet for all connections. Also the control of the emitter X pulses beyond the control, measured by an encoder, was provided by Vision Partners.

"By integrating this vision system by Vision Partners, our operators no longer have to stand in 1 place to check the cans, they can now do other tasks which has increased the efficiency of this production line, reduced costs and made our employees enjoy their work more"