Description case

The line requires reliable quality control at high speed.

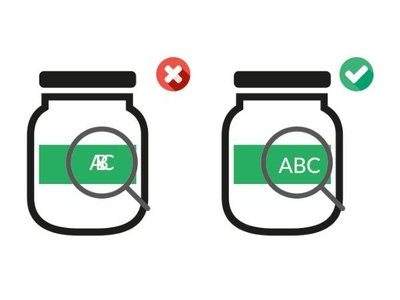

The solution includes two camera modules: a line-scan camera for label analysis and an area-scan module for inspecting cans for dents and fels edges. It checks that the right labels are placed in the right place. The presence of holograms can be confirmed.

All results are logged by batch with image, allowing operators to quickly search back and adjust settings. This improves inspection stability, reduces manual work and increases traceability.

Results in brief

- One combined inspection for label and can inspection

- Integrated PLC for emitter control

- Operator-friendly HMI with live view and quick filtering in log

- Traceability: images and measurements available by batch